Weather: Sunny turning to overcast. Winds: 0-5 becoming stronger and gusty. Waves: <1ft.

First sail post refit.

Day dawned bright and sunny. Had 2 solar amps going into the batteries by 0700! Took a couple strolls on the island and chatted with a couple of folks and learned about the camp visiting raccoons inhabiting the island. About 1000, readjusted the starboard ama and pushed, touring counter clockwise around the island. Dipped into the west cove, checking out the boats and anchoring possibilities. Guide books say it is a tricky anchorage, locals say because of strong currents.

Departed around the south side of the island and headed east towards Skyline. About a mile into Rosario, vicinity of Belle Rock light, winds picked up enough to give sailing a try. Up went the main!

With about 5kts of wind, made about 3.2kts on a reach. Enough to put some pressure on the port ama and ease the pressure on the starboard. Both looked good! Decided to up the pressure by turning more into the wind. With 8kts wind apparent and making 3.8kts, everything still looked good. However, Strider does not like pointing without the jib, just not enough balance and she wants to head up into the wind more. So, unfurled the jib and made 4kts. Amas still looked good! Turned to a beam reach, keeping the sails depowered. Made 4.5kts. While not flying, the starboard ama was really unweighted and the waterstays did not sag. Port side looked solid, with no grunts or groans or moans!

Granted, very benign conditions, exactly what I wanted for first tests, but all looked good! Next step is to check the tension again as the dyneema will continue to settle into its tensioned position. Then, just keep pushing the envelope...bit by bit.

Monday, June 29, 2015

Saturday, 27June2015, Skyline to James Island

Weather: Sunny and hot. Winds: Weak. Waves: Nil.

First test post refit! Motor only in easy conditions.

Loaded aboard, double checked the waterstay tension and net tension. All looked good so we motored out into Burrows Bay and made a right turn towards Rosario Strait, intending to go to Spencer Spit. About 3 minutes out of the gate, ran into a big powerboat wake. Starboard side ama looked good but the port side moved too much. We pulled over and spent 10 minutes readjusting the waterstays. Pressed.

About 1/2 across Rosario, noticed the port side was rock solid but the starboard side was moving a tad. Decided to go to James Island State Park, partly because it was closer and partly because we had never been there. Pulled directly into East Bay and found 2 (of 4) brand new mooring buoys available. As we pulled in, witnessed someone from the boat on the adjacent buoy jump into the 61 degree water. Nuts! Later, I asked how it was. "It lets you know you are alive" was his response!

James Island was nice. Several pit toilets and campsites. Burn ban was in affect because of the dry weather. Nice trails to wander on with some great overlooks. Dogs were excited by something as they kept their noses to the ground and pulling us. Found out via some campers there are raccoons on the island who scattered some trash and kept another dog on alert all night. Saw a river otter and a couple babies on Sunday morning. Kelly said she would go back!

First test post refit! Motor only in easy conditions.

Loaded aboard, double checked the waterstay tension and net tension. All looked good so we motored out into Burrows Bay and made a right turn towards Rosario Strait, intending to go to Spencer Spit. About 3 minutes out of the gate, ran into a big powerboat wake. Starboard side ama looked good but the port side moved too much. We pulled over and spent 10 minutes readjusting the waterstays. Pressed.

About 1/2 across Rosario, noticed the port side was rock solid but the starboard side was moving a tad. Decided to go to James Island State Park, partly because it was closer and partly because we had never been there. Pulled directly into East Bay and found 2 (of 4) brand new mooring buoys available. As we pulled in, witnessed someone from the boat on the adjacent buoy jump into the 61 degree water. Nuts! Later, I asked how it was. "It lets you know you are alive" was his response!

James Island was nice. Several pit toilets and campsites. Burn ban was in affect because of the dry weather. Nice trails to wander on with some great overlooks. Dogs were excited by something as they kept their noses to the ground and pulling us. Found out via some campers there are raccoons on the island who scattered some trash and kept another dog on alert all night. Saw a river otter and a couple babies on Sunday morning. Kelly said she would go back!

Wednesday, June 3, 2015

Major Overhaul 2015 Part 1

Just what is a major overhaul/refit? I'm not sure. Is it over X dollars spent? How about the number of tasks completed? I asked a buddy and he did not know the answer, but suggested Strider's winter 2015 projects fit his definition: "I know it when I see it." So, a major overhaul/refit for Strider in winter/spring 2015. It all began with fiberglass fatigue/failure on the amas, which kept leading to more...naturally.

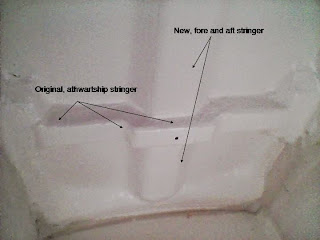

In addition to the external repairs, additional support was added inside. OEM included an athwart support, centered on the pivot bolt. This did fine supporting the structure while extended, but did nothing while folded. There is now an additional fore and aft support (fiberglass with wood core), reinforcing the structure while folded.

I contacted the manufacturer and was quoted about $2200 to replace all, but the material was not in stock, would have ordered, then manufactured, then shipped. I decided to attempt something new with a local rigger and machinist.

We were able to salvage the 3/4" double jaw toggles from the hull side end and the 20mm stud terminal from the aka side. Had a machinist bore out the cable from the 20mm stud and tap the stud for 5/8in-18 T-bolt toggle, like the bottom half of the turnbuckle in this picture.

Locally fabricated 1/2in Cortland Plasma 12 strand synthetic line is used along with thimbles to replace the cables. Weight reduction is 28 pounds. Material cost was about $500. Machining was $300. Labor, including consultations and learning how to assemble the system (watching the rigger splice and sew) was $600. $1400 for new waterstays and done using local talent and material!

UPDATE: This did not work out as planned. The combination 20mm stud and the 5/8 t-bolt toggle was too long and interfered with the ama folding. Fortunately, Plan B was too use the 5/8 t-bolt toggle solo, inserted into the 20mm receptacle. Eliminating the 20mm stud also removed 5 pounds.

Replaced a couple aluminum, 75mm, ball bearing Frederiksen sheaves, worn through by the stainless steel steering cable with a couple 50mm Ronstan RF50000HL sheaves. Though slightly smaller, the sheave is a direct replacement and the Nylatron material is good for cable.

Ama

Fiberglass

Strider is folded most of the time. Folding creates a long lever between the ama and the forward aka with the force focused on the pivot pin. Wind and waves combine to force a scissoring action between the two, fatiguing the ama fiberglass. After several years and possible previous repairs, the ama fiberglass was collapsing. |

| Port Ama Extended |

|

| Starboard Ama Folded |

|

| New fiberglass repair area |

|

| Area Repaired. Black UHMW was selected for the rub rail/skid plate for its alleged UV resistance |

|

| Internal Reinforcement |

|

| Simple scissor preventer. Eye nut on top, 3/16 dyneema with snap shackle in the middle and a U bolt on the ama. Tails at the top are for adjusting the length. |

Solar Panels

I've made mention in previous posts I was not satisfied with the 100 watt solar panel placement. Too far aft and partially shaded by the stays and the net. So, moved them forward, just aft of the ama hatch. This move necessitated the repair of the bolt holes, which were completed with a bit of fiberglass. But since the non-skid color could not matched, the grey, gelcoat non-skid was sanded off and new, off-white, polyurethane/bead non-skid applied. Only the exposed ama top, aft of the panel, got the non-skid. The area under the solar panel is plain off-white polyurethane.Aka

Hinges

Were out of round at the pins allowing the ama/akas to flex while underway. It is a bit disconcerting to see them flapping around in the waves. So, the hinges were removed and brought to a machinist who has fabricated seemingly massive collars/bushings to bring the hinges back into round. |

| Note the large bushing. It was pressed in and then welded. |

|

| Forward half installed. Aka half installed. |

Shoulders

With the amas off and the hinges removed, the shoulder cracks on the vaka were more visible and and more extensive. |

| Forward Starboard |

|

| Aft Starboard |

Swing Wing Cables

These cables are inside the aft aka and used to extend the amas, pulling the ama forward via a line integrated in the net. A couple broken strands were found on a cable indicating replacement is due. So, removed, cleaned and polished the brass aka sheaves abraded by the stainless cables. Used a rubber drum for a sanding wheel chucked in a drill press. Clamped the sheave assembly in a vise and pressed the sheave onto the rubber drum, causing the sheave to spin. Used stiff sand paper to smooth and polish the sheave. Then, replaced the stainless steel cables with 1/4 inch amsteel using heavy duty thimbles. |

| 1/4" dyneema aka cable with red 3/16" dyneema soft shackle. |

Waterstays

With the ama off, was able to inspect the waterstays, the cable preventing the amas from collapsing upward while in the extended position. The waterstays were about 7ft of 14mm stainless cable with a 20mm stud terminal at one end and an eye terminal at the other. One eye terminal had extensive cracks. With one close to failure combined with the manufacturer's recommendation to replace all every 5yrs, I decided to replace all.I contacted the manufacturer and was quoted about $2200 to replace all, but the material was not in stock, would have ordered, then manufactured, then shipped. I decided to attempt something new with a local rigger and machinist.

We were able to salvage the 3/4" double jaw toggles from the hull side end and the 20mm stud terminal from the aka side. Had a machinist bore out the cable from the 20mm stud and tap the stud for 5/8in-18 T-bolt toggle, like the bottom half of the turnbuckle in this picture.

|

| Salvaged 20mm stud with new 5/8in t-bolt with terminals |

|

| New Waterstay Assembly |

|

| The results: Purple is the plasma, blue is 1/4" dyneema lashing. |

Windscreen

Replaced the silicon sealed 1/4" plexiglass with weather stripped 1/8" polycarbonate. The thin polycarbonate was relatively easy to work with. The difficult part was removing all the old, black silicon sealant. |

| Weatherstrip |

|

| New Windscreen |

Rudder Assembly

Removed/cleaned and replaced the bottom fitting, bottom half of the rudder support assembly. Assembly was sloppy in its holes, with about a 1/2 inch swing. So, created a couple stainless bushings by modifying spacers to fit over the assembly bolts and redrilled the fiberglass hull holes to fit the outside diameter of the spacers, now a very tight fit. Used butyl tape with countersink method detailed in this Compass Marine article.Replaced a couple aluminum, 75mm, ball bearing Frederiksen sheaves, worn through by the stainless steel steering cable with a couple 50mm Ronstan RF50000HL sheaves. Though slightly smaller, the sheave is a direct replacement and the Nylatron material is good for cable.

Monday, 9Mar, 2015: Skyline to Anacortes Marina

Weather: Sunny and cool. Winds: Negligible. Waves: Negligible.

Simple motor on a pretty day from Skyline to the east side of Anacortes to begin what would become a 2 month, major overhaul at Marine Servicenter (sic). 5 miles in 1.5hrs against a slight ebb.

Simple motor on a pretty day from Skyline to the east side of Anacortes to begin what would become a 2 month, major overhaul at Marine Servicenter (sic). 5 miles in 1.5hrs against a slight ebb.

Subscribe to:

Posts (Atom)